|

Page Directory

Introduction

What I Like

What I Don't Like

The Bottom Line

Incra2000

JDS Accu-Miter

Final Word

Calibrate It

Site Directory

Home

Tool Reviews

Projects & Plans

Articles

Our Shop

FAQs

Sites I Like to Visit

Build a Kayak

E-Mail Us!

|

|

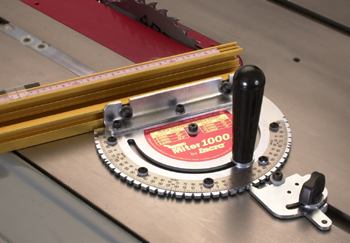

Welcome to our review of the Incra Miter1000 miter gauge. I use several cross-cut sleds (shop-made and Dubby) and several miter gauges including a JDS Accu-Miter and Miter2000 from Incra. I purchased an Osborne EB-2, but returned

it for a number of reasons. Thus, when comes to reviewing the Miter1000 Incra Miter Gauge, I have

a number of accurate and time-tested cross-cut tools to compare it with. All testing was done on

a well-used, but well-tuned Powermatic 66 table saw and a relatively new Grizzly 1023S.

Welcome to our review of the Incra Miter1000 miter gauge. I use several cross-cut sleds (shop-made and Dubby) and several miter gauges including a JDS Accu-Miter and Miter2000 from Incra. I purchased an Osborne EB-2, but returned

it for a number of reasons. Thus, when comes to reviewing the Miter1000 Incra Miter Gauge, I have

a number of accurate and time-tested cross-cut tools to compare it with. All testing was done on

a well-used, but well-tuned Powermatic 66 table saw and a relatively new Grizzly 1023S.

- It is easy to adjust and setup. The miter bar adjusts to fit the saw's miter slot using its

four expandable nylon washers. The miter bar could use additional expansion washers under and/or

behind the protractor head.

- Its angle markings and stops are very accurate. It offers stops at every 5° with additional

stops at 22-1/2° and 67-1/2°. Furthermore, it provides a vernier cursor that allows you to position the

protractor head at precise 1/2° and 1/4° settings. Also, the Incra positive stops are actually

teeth, which from my experience is superior to the variety of shot-pin arrangements I have used (Accu-Miter and Woodhaven).

- Setting angles and returning to 0° is a snap. It always returns to exactly 0° (90°). Again, I like the feel of the engagement of the

protractor head better than the shot-pin arrangement of the JDS Accu-Miter. The Incra tooth engagement does

not have any movement-it feels sure and exact.

- The protractor head swings +90° to -90°. The Incra Miter2000 only provides a +50°/-4° swing.

- Lots of fence options. Depending on where you buy your Miter1000, you will have a choice of a

number of fences. For instance, Woodpeckers offers the new FlipStop fence in 18", 27", and 36"

lengths. Woodpeckers and Eagle-America offer several versions of sub-fences that include

t-slots and toggle-clamp hold-downs. Check out WoodPeckers Incra Site

for the best variety of Incra and third-party accessories.

- My Miter1000 came with the standard SlideStop fence. I prefer it to the more complicated

Miter2000 ShopStop fence.

- The stop is a simple piece of ABS plastic, approximately 3/16" thick. It fastens to the fence

using two thumbscrews and hex nuts.

- The stop provides a vernier cursor that mates to the 16" measuring scale. The setup works well, though I don't like having to tighten two

thumbscrews to set the stop.

- The SlideStop fence does not have the plastic Incra sawtooth track of the ShopStop fence,

that some claim is great because it provides the 1/32nd" positioning capablity. I find the track a

hinderance am glad it's not included on the SlideStop fence.

- The fence does not flex.

- The fence is a little on the small side (18" by 1-1/2") but because of its design (its extruded

t-slots), it easily accepts shop-made and purchased auxillary fences.

- Incra/Woodpecker offers auxillary fences for a nominal price.

- The Miter1000 manual provides detailed instructions for making and installing auxillary

fences.

- The optional FlipStop fence and FlipStop is a winner. Incra kindly upgraded my original

ShopStop fence with the 27" FlipStop fence and stop. Both items are marvels of Taylor Design (Incra)

engineering.

- The fence is very solid and has a good feel to it.

- The fence provides a number of T-Slots to simplify attaching a sub-fence.

- The fence face is ribbed which allows saw dust to escape.

- The fence came with mylar attached to the bottom to reduce friction when sliding it across the

saw table.

- The fence still has the two-piece measuring scale. I don't believe that they cannot purchase or

manufacture accurate scales longer than 16". Oh Well...at least they're consistent...

- The fence and stop have the Incra position tracks. Doubt I will use them, but they could be useful.

- The stop consists of two flip arms that both flip up and out of the

way when not needed.

- The flip arms engage with ribs on the fence fence to prevent the sharp corner of a mitered

edge from wedging between the flip arms and the fence. This is a sore point I have with the

Incra ShopStop fence and stop.

- The stop is engineered to accept an auxillary stop. Cool idea.

- The flip arms have stop rods. Incra supplies one long rod that connects the arms and two shorter

rods so that you can use the flip arms independently. Unfortunately, the flip arms really are not

independent since they are mounted to the same base. Typically, independent flip arms are truly

independent.

- The stop base provides two sets of T-Slots for the flip arms. This allows you to use the stop

with a 3/4" thick sub fence.

- You can micro-adjust the stop assembly and flip arms at least three ways:

- Incra positioning racks are built-in to the fence and stop assembly. The racks allow you

to position the stop in 1/32" increments.

- The stop has a micro adjuster consisting of a fine thread Allen-head screw. It works great, but,

you must loosen two Allen-head screws to loosen the flip arm assembly--not very practical.

- You can loosen and reposition the short stop rods.

- The flip arm assembly extrusion allows you to use the micro-adjuster with the flip arm assembly

mounted in the front position (for use with a sub-fence). Cool.

- The stop assembly is locked down using two plastic knurled knobs. With all the trick engineering,

this seems to be a bit lame. I don't like having to tighten two knobs to lock down the stop. I'll get

over it.

- The Miter1000 works in either miter slot by simply sliding the fence left/right to clear the blade.

- You can slide the fence as close to or as far away from the blade as you like.

- The ruler/scale moves left and right in its slot atop the fence. This allows you to easily adjust it when rotating the protractor head for

angles.

- The protractor, miter bar, and fence are all nicely finished. The protractor scale is nicely (and finely) etched

stainless steel.

- Like the Miter2000, the protractor head has a label that provides a quick reference chart that associates 4,6,8,9,

12,and 18-sided objects to their protractor settings. A nice touch.

- The Miter1000 protractor head extends only 7" behind the face of its fence. Compared to its Miter2000 big brother,

the Miter1000 head is easier to control and just feels better to use than the Miter2000.

- The ABS plastic sub-base helps the protractor head slide a little easier than conventional miter gauges.

- Excellent Manual.

- Comes with all Allen wrenches used during installation and setup. Also includes a handy, handled,

ball-Allen wrench for adjusting the fence/protractor Allen-head screws.

- At $99.99, the price is right!

- The standard fence is only 18" long and 1-1/2" tall. For the price, it is actually a good fence and is well finished. But for a fence,

it is on the small side. I figure most buyers will purchase other Incra fences or attach a sub-fence.

- The stop requires that you tighten two smallish thumbscrews to lock it in place. It works fine,

but probably would not be tolerated by professional cabinet or production shops. Luckily, the fence is

designed so that you add shop-made stops.

- The stop does not flip out of the way. It is a flat piece of ABS plastic that simply slides

left and right along the fence. You have to remove the stop if you want to cut a work piece longer

than 17-1/2".

- The ruler/scale moves left and right in its slot atop the fence. This allows you to knock it out

of adjustment. Oddly, the scale is only 16" long, leaving a full two inches of fence without a

measuring scale.

- The miter bar is made to fit a wide range of miter slots, thus it is purposely made very narrow

relative to the standard .750 wide slot. The expansion washers are designed to expand to fit the slot. I

have difficulty getting them "just right". Either they're too tight or too loose.

- The unit feels flimsy compared to the JDS Accu-Miter. In fact, after using it for a day I went back to the

JDS Accu-Miter--the Incra just doesn't have enough meat for my liking. I actually fit the Accu-Miter fence onto the Miter1000

and it felt better but I noticed that the additional weight of the JDS fence accentuated any miter bar slop.

- How long will the ABS plastic sub-base last?

- This complaint is aimed at any conventional miter gauge: Once you have used a crosscut sled

(Shop-Made, Dubby, Biesemeyer,etc.), you get used to the support the sled gives to the bottom of the workpiece as well

as to the trailing edge. This bottom support provided by the crosscut sled reduces the chance for

error by reducing virtually any chance that the workpiece is going to rotate or shift as you push

it through the blade. This is particularly noticeable when cutting panels or wide workpieces. This why

I do 90% of my crosscutting using the Dubby or my shop-made sleds.

- If I buy another miter gauge, SHOOT ME! Crosscut sleds, sliding tables, etc. are a far better way

to crosscut. After cutting miters on short work pieces with the Miter1000 I asked myself, why

not use the Dubby? Its clamp holds the work against the base and fence leaving my fingers far away

from the blade. Sure, you can setup a clamp on the miter gauge, but I have not had a lot of luck

with miter gauge clamps on table saws.

The Miter1000 performs as advertised. Its stops are very accurate and completely repeatable.

The variety of available fences and sub-fences is a real plus when comparing the Incra miter gauges with

those of other manufacturers. I can recommend the Miter1000 at the going price of $100. But I will

continue to use my Dubby, crosscut sleds, and the JDS Accu-Miter for the majority of my crosscutting chores.

In my humble opinion, the Miter1000 is a better all-around miter gauge than the Miter2000. The Miter2000 provides twice as many

stops, but most woodworkers will never use them. The Miter1000 protractor however offers the +90/-90 rotation

that I think most woodworkers appreciate. I like the feel and overall usability of the Miter1000

hands down over the Miter2000. However, woodworkers needing or wanting stops at "odd"

angles may find the Miter2000 to be a better deal. Again, Incra addressed my major gripes

of the Miter2000 with their introduction of the FlipStop fence.

I like the JDS Accu-Miter a lot. I like its solid feel and once I worked out a manufacturing

flaw, it returns to angles very reliably. The Accu-Miter stop is much more functional than the

Incra SlideStop and the JDS Fence is more robust. However, if you mate the Incra Miter1000 with the new 27" or 36" FlipStop fence and stop, the Incra is probably a better deal for most amateur woodworkers, turners, and artisans who require or want all of the stops. However, for small furniture and cabinet shops, the JDS Accu-Miter paired with a Dubby or other crosscut table is still a hard combination to beat.

I have owned and used the Osborne EB-2, the Woodhaven Standard Miter Gauge and FastTrack fence,

the JDS Accu-Miter, the Incra Miter1000, the Incra Miter2000, and the Delta,

Powermatic, and Grizzly miter gauges. All of them are flawed. None of them match the accuracy,

ease of use, and utility of a crosscut sled (Dubby or homemade), sliding table, or other device that provides both a

fence and a base for the work piece.

We recently toured several medium sized furniture shops and one large furniture shop in Iowa. We counted more than a

dozen cabinet-type table saws in the shops and all but one had the standard miter gauge (most had a wooden subfence).

The lone aftermarket miter gauge was a Woodhaven. Virtually every saw had one or more shop-made crosscut sleds in

use or hanging nearby.

There are numerous ways to calibrate crosscut devices to be square with the blade. Unfortunately, using a carpenter's square or even a machinist's square does not always cut it. There are three methods that are regarded as being the best practice methods for squaring a crosscut device (miter gauges, sleds, and sliding tables). Click Here to read about and view demonstrations of three methods for calibrating crosscut devices.

Was this article helpful? Do you have any questions? E-Mail Us! We would love to hear from you!

|