|

|

|

|

A few notes from Jerry Golick regarding Festool, the Festool MFT, and so forth:

A Festool Owner's Group has been started on yahoo, and there have been some interesting discussions on Festool and other GCSS (Guided Circular Saw Systems) on the Saw Mill Creek forums. I also came across someone who has built a low end, but pretty nice panel cutting table using Festool's AFT65 at Brad's Panel King Web Site. A little expensive for my tastes, but kinda interesting.

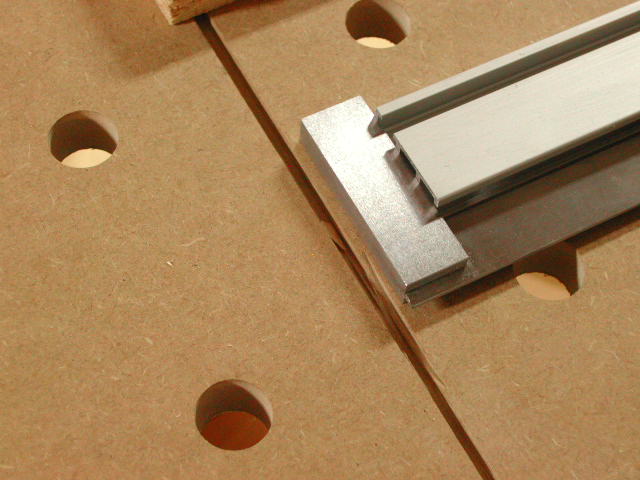

Also, I have heard about a company called 8020 (www.8020.net) that makes aluminium t-slotted extrusions that will fit the festool components such as the guide brackets on the MFT.

I have been finding many uses for my MFT1080. I ordered a pair of the FS-Rapid clamps and was pleased to see they could be attached not only to the underside of the guide rails, but also to the t-slots on the side of the table. This allows me to clamp things on any side of the table which has proven quite useful.

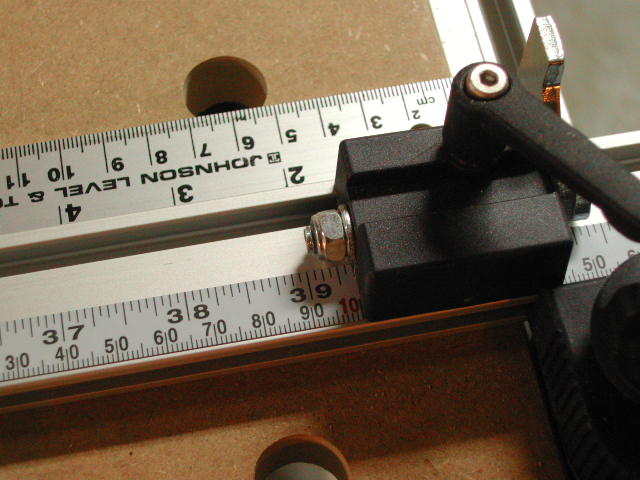

While I very much agree with John Lucas' suggestion of placing a measurement tape on the mitre rail, I disagree somewhat with his technique of putting it on. John measures from the edge of the kerf line on the table.

The problem with this idea is the size of the kerf may vary depending on both the blade being used (Festool blades range between 2.2 and 2.6mm) and the bevel angle. Plus, if the fence ever has to be moved you have to go through the "true up" process again.

My technique involves measuring from the blade itself. I use a ruler and butt it up against the blade and then set fence to the proper length. Once the fence is set at the correct length I tighten it down. The whole process takes about 2 minutes.

I sometimes use the longitudinal stop as a way to true up pieces of work when I am making a narrow cut. I find this very helpful when I am cutting narrow rails for the inside of the cabinets.

I feel that Festool makes wrong recommendation in placing the bracket for the mitre fence in holes 4-5 on the MFT. Doing in this way means you can only swing the fence to about 79 degrees before it gets in the way of the guide rail. I think holes 5-6 would be a better choice.

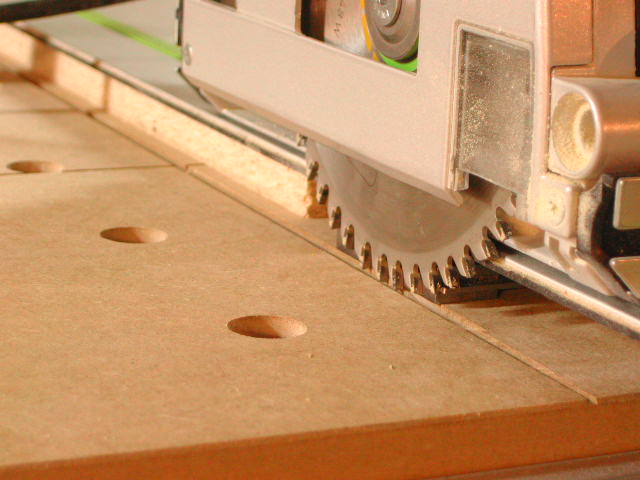

When I am using the LR-32 hole making system I have found the FS-Rapid Clamps to be a superior way to attach the guide rail to the panel. Using this approach allows me to quickly set the guide on each panel without having to use the somewhat awkward clamps that come with the kit. Note that I have to have another piece of material underneath the panel to raise it high enough to clear the Rapid Clamps.